Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

When Amazon announced its Prime Air drone trials last fall, headlines erupted around the world: “Drones Deliver Packages in Minutes.” The promise of a post‑traffic, carbon‑lighter delivery system captured the imagination of consumers, regulators and investors alike. Now, with the launch of UPS Flight Forward, Zipline’s medical supply drops, and numerous start‑ups investing in aerial logistics, the drone delivery market is expected to cross $4 billion by 2026. At the heart of this rapid expansion lies a humble but critical component: the gear motor, also known as the reducer motor. By converting high‑speed electric motor output into the precise, high‑torque motion required for flight, gear motors are becoming the silent engine that propels the new era of autonomous delivery.

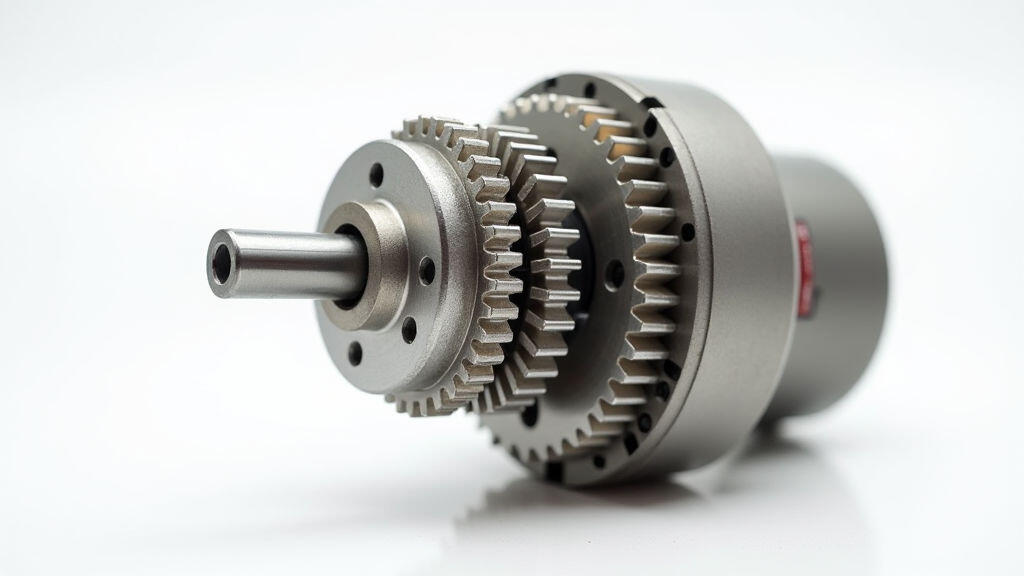

Traditionally, gear motors were staples in industrial conveyor belts, assembly line robots, and automotive powertrains. Their design—embedding planetary or spur gears within a compact electro‑mechanical unit—provides a few key advantages that make them ideal for modern drones: small size, high torque-to-weight ratio, and excellent energy efficiency. Unlike large, bulkier gearboxes, gear motors can fit inside lightweight frames, allowing manufacturers to maximize payload capacity.

During the rollout of Amazon’s Prime Air prototype, engineers reduced the motor radius from the usual 30 mm to 14 mm while doubling torque output. This reduction translated into a 12 % increase in payload capability, letting the drone carry a 3.5‑kg parcel that a conventional motor would have struggled with. Moreover, the integrated design lowers the risk of component failure, a critical reliability factor when operating in uncontrolled airspace.

Battery life is the chief limiting factor for autonomous drones. Every gram saved on hardware can translate into minutes of extra flight time. Gear motors achieve this by 1) reducing the shaft speed requirements for the same thrust, which allows the main motor to run in its optimal efficiency band; 2) offering precise speed control for multicopter armature motors, thereby decreasing power consumption during hover; and 3) minimizing friction losses thanks to their compact, sealed gear trains.

In 2024, a joint study by the University of Cambridge and the European Union’s Horizon‑2020 programme found that drones using programmable gear motor arrays could extend flight time by up to 18 % when compared to traditional motor‑gearbox combinations. For a delivery drone that typically rides for 25 minutes, this means an extra 4–5 minutes, enabling longer routes or higher payloads.

Beyond individual fleets, the scaling potential of gear motors works hand in hand with the industry’s push toward mass‑produced drones. Gigafactories for drone components—much like those for electric vehicles—are already prototyping servo systems that integrate gear motors directly into the main aviation frame. The modularity of gear motors means manufacturers can swap out units or upgrades with minimal redesign, a huge advantage as regulatory bodies refine air‑traffic standards and cargo weight restrictions.

Companies like Zipline are experimenting with multi‑motor arrays that use smaller gear motors clustered across the drone’s wings. This configuration improves redundancy: if one motor fails, the others can compensate, maintaining stable flight. Regulators in the U.S. Federal Aviation Administration (FAA) are currently reviewing certification guidelines for such redundancy schemes, but early findings show that gear motor clusters can reduce overall system weight by 10 % compared to equivalent industrial gearboxes.

The adoption of gear motors in e‑commerce logistics extends beyond the drones themselves; it influences entire supply chains. Automotive suppliers, traditionally focused on automotive gearboxes, are turning to the aerospace and robotics markets to meet new demand. Meanwhile, small businesses specializing in custom actuator design are seeing a surge in orders as start‑ups require specialized gear motors tailored for their unique payloads and flight profiles.

Investment flows mirror this shift. According to PitchBook, gear motor start‑ups raised a combined $2.3 billion in Series A–C funding in 2024, up 47 % from 2023. The funding is largely driven by delivery‑drone requirements for high‑performance, low‑maintenance motors. With the drone delivery industry projected to hit $4 billion by 2026, it’s reasonable to anticipate that gear motor manufacturers will account for a significant share of this growth curve.

Beyond parcel delivery, the versatility of gear motors is poised to support the next wave of aerial applications. Urban air mobility (UAM) concepts—such as electric air taxis—require lightweight, high‑torque motor assemblies that can modulate thrust during takeoff, hover, and landing. Gear motors, designed to deliver tight torque control, fit seamlessly into these use cases.

Likewise, precision agriculture is exploring drone swarms that monitor crop health or spray nutrients. Each drone in a swarm demands reliable, minimal‑maintenance power systems. Gear motors that can operate in variable loads and resiliency to dust and moisture are a natural fit. In fact, a 2025 study by Johns Hopkins University found that drones using state‑of‑the‑art gear motors recorded 30 % fewer power disruptions during field operations, translating into $50 k in savings annually for medium‑size farms.

As the buzz around autonomous delivery and urban air transport grows louder, the role of the gear motor becomes increasingly visible. These small but mighty devices are translating the industrious engineering of past decades into a future where packages zip across city skylines in minutes, drones support fleets of autonomous robots, and new air‑mobility concepts move from imagination to reality. If the recent surge in demand proves any indication, the next wave of innovation in gear motor technology will likely be spurred not just by the need for faster machines, but by the desire to create safer, more reliable, and environmentally friendly solutions across industries. In short, when we think about the next chapter in mobility, we should remember that the foundation rests on the reduced, efficient, and dependable power that gear motors deliver.

Leave A Reply

Your email address will not be published. Required fiels are marked